Kubalulekile ukuhlola uhlobo lokunamathela ngaphambi kokusebenzisa izitikha zelebula yokumelana nezinga lokushisa eliphezulu. Ukuze ubone ukuthi iyiglue esekelwe emanzini noma encibilikayo. Ezinye izinto ezinamathelayo zizosabela ngamakhemikhali nezinto ezithile.

Isibonelo, izitika ezizinamathelayo ezisetshenziswa njengamalebula zingangcolisa izindwangu ezithile ezikhethekile ngaphansi kwesimo esithile. Ezinye izitika ezidinga ukunamathela kwesikhashana zizodala ukunamathela okuhlala isikhathi eside ngaphansi kwezimo zokuchayeka. Ngokuphambene nalokho, ezinye izitika ezidinga ukunamathela okuhlala isikhathi eside zizolahlekelwa i-viscosity yazo ezindaweni ezithile.

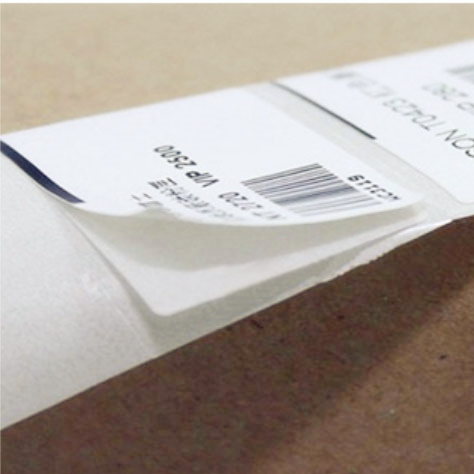

Amanye amakhasimende anempendulo yokuthi ilebula ayinamatheli kakhulu. Izizathu ziyinkimbinkimbi futhi zihlukahlukene. Amanye amakhasimende antula ulwazi lwemboni azocabanga ukuthi izinga lezitikha alilihle. Eqinisweni, izinto zethu zelebula zokuzibamba zivela kubakhiqizi abaziwayo, ayikho inkinga yekhwalithi. Amanye amakhasimende angase angazicacisi izimfuneko zokunamathela noma enze uhlolo ngaphambi kokunamathisela, kungase kuholele ekutheni i-viscosity yayo ingahlangabezani nezidingo ezifanelekile zamakhasimende.

1. Ukunamathela kokuqala:evamile indlela yebhola eliginqikayo. Lungisa uhlangothi olunamathelayo phezulu endaweni ethambekele, bese ucindezela amabhola ensimbi ajwayelekile anosayizi abahlukene ashelele phansi ukusuka phezulu. Ibhola elikhulu lensimbi linganamathela, ukunamathela okukhulu kokuqala elinakho.

2.Ukunamathela unomphela:sebenzisa amalebula ukuze unamathisele amapuleti ensimbi amabili ajwayelekile anamahhuku, bese ulenga ipuleti elilodwa lensimbi kuhlaka olungaguquki, bese ubeke isisindo esingu-2kg ngakolunye uhlangothi ukuze ubone ukuthi ipuleti lensimbi elingezansi ngeke liwele phansi, ubala ukuthi lizohlala isikhathi esingakanani.

3. Amandla okukhumula:Namathisela ilebula ku-steel plate evamile, susa ilebula ngesivinini esingaguquki ngethuluzi, amandla asetshenziswa ithuluzi angamandla okuhlubula esitikha.

Umqondo ojwayelekile wokuthi ungabakhetha kanjani abakhiqizi belebula ezinamathelayo ezikwazi ukumelana nezinga lokushisa eliphezulu, okulandelayo ngamathiphu ayi-10 akho:

1.Ngokuvumelana ne-adhesive surface material yomkhiqizo

Amalebula ethu ayazinamathela futhi angase anamathele phezu kwezinto ezihlukahlukene, njengengilazi, insimbi, amakhadibhodi kanye nepulasitiki. Futhi ipulasitiki ingabuye ihlukaniswe ibe yi-polyvinyl chloride kanye ne-polyethylene ephakeme kakhulu. Ukuhlola kubonise ukuthi indawo yokulebula ehlukene ibe nomthelela omkhulu ekusebenzeni. Ngakho-ke, lapho sikhetha ilebula yokuzinamathisela, kufanele sinqume ukuthi hlobo luni lwelebula lokuzinamathisela okufanele silikhethe ngokuya ngendawo yokunamathisela okudingeka inamathele kuyo imikhiqizo yethu.

2, Ngokuvumelana nokuma kwendawo yokunamathela yomkhiqizo

Ingaphezulu lento enelebula ingahlukaniswa ibe indiza eyodwa futhi ibe yinye agobile. Uma indawo yokulebula ine-arc ethile (isibonelo, Ingaphezulu lebhodlela lomuthi elingaphansi kuka-3 cm ububanzi), ingase idinge ukuthi isitokwe sobuso sinokuvumelana nezimo okuhle noma ingcina i-high-tack.

3, Ngokuvumelana nokuhlanzeka kwendawo enamathelayo yomkhiqizo

Izinto ezizinamathiselayo zifaneleka kakhulu endaweni ehlanzekile, eyomile, eyomile, eyomile, eyomile, eyomile, engawoyela neyothuli, uma ingezinye izinhlobo ze-substrate, sicela ukhethe elinye iphepha lelebula lochwepheshe.

4, Ngokuvumelana nezimo zemvelo

Indawo yokulebula kanye nezinga lokushisa kuzothinta izici zokunamathela, njengendawo enamanzi amaningi noma kawoyela amaningi. Amalebula azinamathelayo adinga ukunamathiselwa ngaphansi kwezimo ezibandayo, ezishisayo, ezinomswakama noma zegumbi.Kungakhathaliseki ukuthi isitikha sichayeka endaweni ezungezile engaphansi kwendawo yokubanda, kungakhathaliseki ukuthi sisetshenziswa ngaphandle, ngaphansi kwezinga lokushisa eliphezulu, umswakama noma ukukhanya kwe-ultraviolet, nokuthi kuseduze yini nezinga lokushisa eliphezulu lenjini yemoto nezinye izimo ezidinga ukucatshangelwa. Ngakho-ke, iphepha lelebula elifanele kufanele likhethwe ngokuvumelana nezimo ezihlukahlukene zemvelo. Isibonelo, ilebula yesithando somlilo sebhodi lesifunda se-PCB embonini ye-elekthronikhi kufanele ikhethelwe ingcina ekwazi ukumelana nokushisa okuphezulu(izinga lokushisa eliphakeme elingu-350℃).

5, Ngokuhambisana nezici zokunamathisela ilebula

Ngokuphathelene nokusebenza kwezinamathiselo, zingahlukaniswa zibe izigaba ezimbili: i-adhesive unomphela kanye ne-adhesive ekhishwayo. I-adhesive unomphela kunzima ukususa, ukusebenza kwayo okunamathelayo kunamandla. I-adhesive ekhiphekayo kulula ukuyisusa, futhi ukusebenza kwe-adhesive akukuhle njengokunamathela unomphela.

6, Ngokusho kwe-pukurinta kanye nezindlela zokucubungula

Ekukhetheni izindlela ezihlukene zokuphrinta (njengokuphrinta kwe-flexography, ukuphrinta kwe-letterpress, ukuphrinta kwe-offset, ukudluliswa kwe-thermal nokuphrinta nge-laser) nezindlela zokucubungula (ezifana nomqulu ukuze ugoqe, ugoqe uye eshidini, ukugoqa ephepheni, ishidi kuya eshidini) ngaphambi kokunquma into enamathelayo, kufanele ihlolwe ngezimo ezifanayo zokuphrinta, ukucubungula kanye nokulebula. Ukukhethwa kwe-face-stock kuncike endleleni yokuphrinta kanye nezidingo zokugcina zekhasimende. Ukunyathelisa okuseqophelweni eliphezulu ngokuqinisekile kudinga iphepha elibushelelezi kanye nezinto ezinhle kakhulu zangaphakathi zokuzinamathelisa. Ukuphrinta kokudlulisa okushisayo kudinga ukuthi i-facestock iyiphepha elikhethekile elibushelelezi nelimelana namabala.

7. Ngokushoiisikhathi sokugcinaudinga

Imikhiqizo ehlukene kanye namakhasimende ahlukene anesikhathi esihlukile sokugcina amalebula wokuzinamathisela, amanye adinga isikhathi eside, okunye adinga kungase kube okwesikhashana, ngakho-ke kudingeka sinqume futhi sikhethe ngokuvumelana nezidingo zethu zamalebula wokuzinamathisela, ukuze singachithi izinsiza zethu zezimali.

8,Pay Okuningiukunaka umkhuba weglue ngokweqile

I-PVC ethambile kanye nelebula yekhodi yebha ye-PET ivamise ukuba ne-exudation ye-plasticizer eyaziwa nangokuthi yi-squeeze-out. Lapho ukhetha ilebula yekhodi yebha ye-PET ne-PVC, kufanele sinake kakhulu ukukhetha iglue esekwe emanzini. I-hot-melt glue kulula ukuchichima.

9. Ngokushowakho bar ikhodiilebulausayizi

Uma ungaqiniseki ukuthi usayizi wephepha lekhodi yebha ufanelekile, kufanele sinake ukuhlolwa kwangempela, ukuvimbela icala lokuthenga emuva kodwa ngeke lisetshenziswe.

10,Ngenza lukuhlolwa komshini we-abeling

Ngaphambi kokuthenga ilebula yekhodi yebha, kubalulekile ukubeka ilebula yekhodi yebha emshinini wokulebula ozenzakalelayo ukuze uthole izivivinyo ezimbalwa zangempela ukuze uhlole ukushelela kokulebula nezinye izimo.

Ilebula yekhodi yebha iyadingeka kuwo wonke amabhizinisi amakhulu. Eqinisweni, ukukhetha ilebula yekhodi yebha akulula. Isikhathi esiningi, kukhethwa ilebula yekhodi yebha yekhwalithi ephansi. Kubalulekile ngathi ukuthi siqoqe ulwazi oluthile futhi sifunde ulwazi oluthile kusengaphambili ngaphambi kokuba sithenge ilebula yekhodi yebha ukuze sigweme ukuthenga embi kakhulu. Amakhono okuthenga adingekayo womkhiqizi wezinto ezinamathelayo omelana nokushisa okuphezulu kufanele abe yingcweti

Isikhathi sokuthumela: Nov-18-2022